1. Introduction of corrugated plastic panel

Corrugated plastic panel, also known as PP plastic hollow board, corrugated plastic sheet and coroplast sheet, is a combined product of polypropylene and other functional preparations. Its overall compression resistance, ductility, and plasticity are very strong. During use, it can ensure its own integrity to the greatest extent. For customers It brings super strong use effect, the service life of high-quality corrugated plastic panel is very strong, it can be used continuously for 2 to 5 years, and the cost performance is very high. Therefore, corrugated plastic panels are becoming more and more popular all over the world.

2. What are the advantages of the corrugated plastic panel?

The corrugated plastic panel has the effect of waterproof and moisture-proof. In rainy and bad weather, it can protect the products in the corrugated plastic box.

It has corrosion resistance and can be used to package products with chemical components.

It is very light in weight, easy to carry, and greatly reduces manpower.

The compressive resistance of the corrugated sheet is very good, and the corrugated plastic sheet itself can bear about 60KG of gravity. If it is matched with other accessories, the bearing capacity can be stronger.

The most internationally recognized advantage is its environmental protection function, the large corrugated plastic sheets are made of non-toxic polypropylene, which are not harmful to the environment.

Therefore, the worn corrugated plastic panel can also be recycled and reused, reducing unnecessary waste of resources.

It also has the characteristics of anti-aging, and is more durable than ordinary boards, especially cardboard.

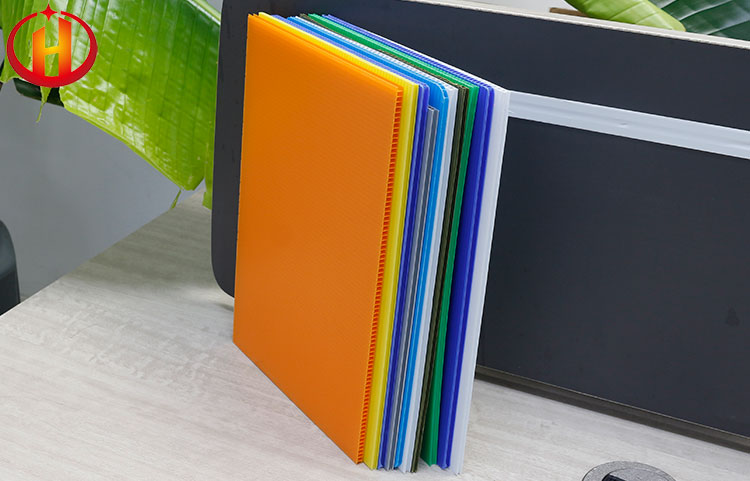

The color of the corrugated plastic sheet is rich and colorful, and the color you need can almost be satisfied in the market.

Its functions are also very rich, and the suitable hollow board can be selected according to the requirements of use. Such as: anti-static, flame retardant, anti-UV, conductive and other special properties of the sheet.

3. Which industries can corrugated plastic panels be used in?

Hardware industry - Due to the irregular shape and size of hardware parts, people can use corrugated plastic panels to customize hardware packaging boxes.

Medical industry - We often see hospitals use trays made of corrugated plastic boards to classify and place different medicines to facilitate dispensing of medicines to patients.

Maternal and infant industry - The most common is the baby stroller. The corrugated plastic sheet is used as the back board, which is safe and light. Of course, some children's toys often use hollow boards as accessories.

Express industry - This industry needs to frequently turn over different products. The characteristics of the corrugated plastic panel, such as durability, lightness and recycling, just meet the needs of the industry, and gradually replace the traditional carton. So the hollow board logistics box came out.

Household industry – Large corrugated plastic sheets can be used to make household storage boxes and wardrobes, which solves the problem of rationally arranging space for families.

Food industry - In the food industry, the most difficult to transport is brittle glass canned food. The corrugated plastic panel can be directly used for the layer pad, which successfully prevents the collision between the products.

Other industries.

4. the choice of different thickness of the hollow board

Corrugated plastic panels of different thicknesses have different uses. The general thickness is 2-12mm.

The 2mm corrugated plastic sheets are generally used for floor protection. Because the correx floor protection is generally used in a large amount, it is often used as a temporary protection board in the field of decoration. Therefore, the 2mm board is the most economical.

3mm corrugated plastic sheets are generally used for light cargo handling and packaging, such as layer pads

4mm corrugated plastic sheets and 5mm corrugated plastic sheet are generally used for outdoor billboards and product packaging. This thickness is suitable for most products, so there will be more stock on the market.

The hardness of the 6mm corrugated plastic sheets will be stronger. Generally, it is used for packaging and turnover of heavy-duty precision instruments, and the anti-collision effect will be better.

According to the characteristics of different products and the requirements of customers, the thickness can be customized, generally the maximum thickness can reach 12mm.

According to the detailed introduction of the corrugated plastic panel above, we have a deep understanding of the unique advantages, wide range of uses and rich choices of the sheet, which is also an important reason for the increasing demand of the corrugated plastic panel in the global market.

5. Huiyuan Plastic is a professional corrugated plastic panel manufacturer

Our company has been relying on technological progress, equipment updates and continuous training of employees to ensure the company's position in the plastics industry. The company will continue to uphold the spirit of quality service and integrity management as the foundation of business operations, and sincerely cooperate with customers and help each other. We will stick to our credibility and promises, and serve our customers wholeheartedly. Welcome to visit corrugated plastic sheet manufacturer.

If you want to buy corrugated plastic panel or corrugated plastic products, you can contact us immediately.

By continuing to use the site you agree to our privacy policy Terms and Conditions.