In today's fast-paced manufacturing and logistics industries, choosing the right packaging material is more important than ever. While cardboard has long been a go-to option, plastic packaging is rapidly gaining traction as a more efficient, cost-effective, and sustainable alternative. This article explores the pros and cons of plastic and cardboard packaging in industrial settings—and helps you determine which is best for your needs.

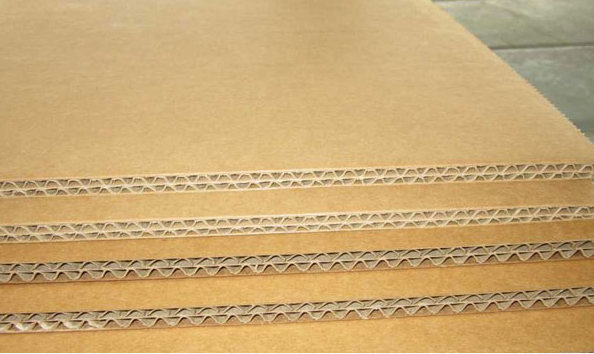

Cardboard is widely used due to its low cost and ease of availability. However, when it comes to industrial applications, especially those requiring strength, durability, and moisture resistance, cardboard quickly shows its limitations:

Single-use nature: Most cardboard boxes are designed for one-time use, contributing to increased packaging waste.

Low water resistance: Cardboard easily absorbs moisture, making it unsuitable for humid or outdoor environments.

Lack of durability: Cardboard collapses or deforms under heavy weight, especially during transportation or stacking.

Short lifecycle: Frequent replacement adds to long-term operational costs.

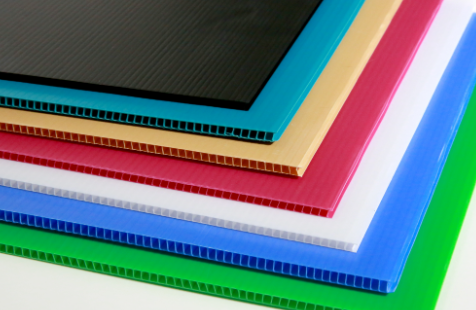

Plastic packaging—particularly solutions made from polypropylene (PP) or HDPE—offers a range of benefits that make it ideal for demanding industrial environments:

Plastic containers are robust and can withstand repeated handling, stacking, and impact. They're resistant to crushing and deformation, offering better protection for valuable goods during transport.

Unlike cardboard, plastic packaging resists water, chemicals, and most solvents. This makes it suitable for industries like automotive, agriculture, food processing, and electronics.

Plastic boxes and containers can be reused hundreds of times. At the end of their lifespan, they can be recycled—supporting your company’s sustainability goals and reducing long-term costs.

Plastic packaging can be customized in size, color, branding, and internal structure (like corrugated plastic dividers). Many designs are also collapsible to save storage space.

Automotive: Reusable pallet boxes and anti-static dividers for storing complex parts.

Logistics: Foldable containers for warehouse and return logistics reduce shipping volume.

Agriculture: Ventilated plastic crates preserve freshness better than soggy cardboard boxes.

Retail: Branded plastic bins offer better presentation and lifespan than traditional packaging.

While plastic packaging offers numerous advantages, it’s not without challenges:

Higher upfront cost: Plastic packaging usually requires a larger initial investment than cardboard.

Not ideal for single-use: If your supply chain doesn't support reusable packaging, plastic may not be the most cost-effective option.

However, in most B2B industrial applications, the long-term savings and durability far outweigh the higher initial cost.

In industrial packaging, reliability, durability, and sustainability matter. While cardboard remains useful for lightweight or temporary uses, plastic packaging offers clear advantages in long-term industrial performance.

If your business is ready to transition to more efficient, reusable packaging, Suzhou Huiyuan Plastic Products Co., Ltd. can help. We specialize in customized plastic packaging solutions for industries such as automotive, logistics, agriculture, and more.

Contact us today to learn how our PP corrugated boxes, dividers, and plastic pallet containers can reduce your packaging costs and boost operational efficiency.

By continuing to use the site you agree to our privacy policy Terms and Conditions.