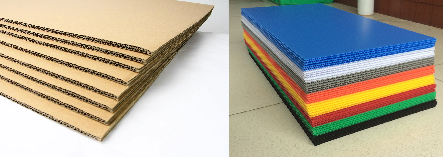

Plastic corrugated sheet, also known as hollow board, is made from polypropylene (PP) or polyethylene. It is mainly used in industrial packaging to protect products during transportation and storage. Due to its durability and reusability, it is increasingly replacing traditional cardboard in the industrial sector.

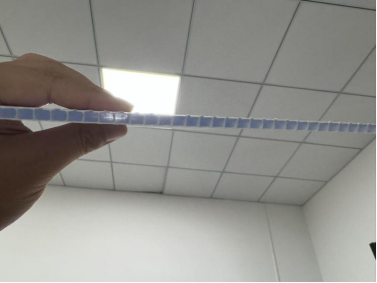

The unique internal structure of plastic corrugated sheets is the key to their strength and popularity. These sheets consist of two flat outer layers with ribbed support in the middle, distributing stress evenly and providing excellent rigidity.

High Strength: Internal ribs distribute surface force, increasing overall durability.

High Rigidity: More rigid than cardboard or regular plastic boards.

Excellent Compressive Resistance: Maintains shape under pressure, offering superior protection.

The production of plastic corrugated sheets involves plastic extrusion and shaping through molds. The process includes:

Most hollow boards are made from polypropylene resin pellets. Additives like anti-static, UV protection, flame retardants, or reinforcements can be included to enhance performance.

The molten resin is pushed through a mold using a twin-screw or single-screw extruder. The mold's structure determines the type and dimensions of the board.

Freshly extruded sheets are cooled and shaped via vacuum and cooling systems to ensure smoothness and dimension stability.

Sheets are cut into required sizes or rolled for easy transport and storage.

Lightweight & Cost-Effective: Reduces shipping costs and makes handling easier.

Reusable: More durable than cardboard, supports long-term cost savings.

Eco-Friendly: Made from 100% recyclable polypropylene, supporting sustainability goals.

Strong Chemical & Physical Properties: Moisture-proof, corrosion-resistant, and abrasion-resistant.

Suzhou Huiyuan Plastic Products Co., Ltd. was founded in 2008 and brings over 17 years of experience in plastic packaging. We have 19 production lines and provide OEM/ODM services for customized hollow boards. Our products are widely used across logistics, automotive, agriculture, and e-commerce sectors. With a professional R&D team, we offer complete packaging solutions tailored to your business.

Website: https://www.huiyuansjplastic.com/

Email: hy331@huiyuansj.cn

By continuing to use the site you agree to our privacy policy Terms and Conditions.