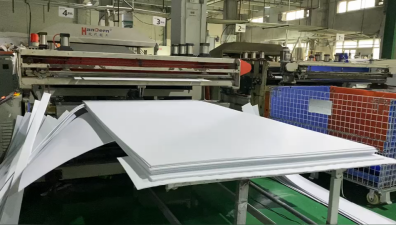

Plastic corrugated sheet (also known as PP hollow board or plastic corrugated board) has been widely used in industrial packaging, logistics transportation, electronic manufacturing, automotive parts, protective partitions and many other fields due to its light weight, strength and recyclability. One of the key factors determining the quality of hollow board is its extrusion process.

This article will delve into the extrusion molding technology of plastic hollow board, focusing on the differences and applications of single-screw and twin-screw extruders, to help you fully understand the features of Huiyuan products and their advantages over other products.

Single screw extruder, as the name suggests, consists of a single screw. The screw rotates and stirs within the barrel of the machine. The rotation of the screw drives the plastic particles forward, melts them, mixes them, and extrudes them into a shape.

Twin-screw extruder, as the name suggests, consists of two screws. These two screws usually rotate in the same direction (Co-rotating) or interlock with each other, and there are also structures with opposite rotations. Through the collaborative work of the two screws, the material experiences more uniform force during the processes of shearing, mixing, and extrusion.

The single screw extruder has only one screw and its mixing capacity is relatively weak. It is only suitable for homogeneous raw materials and the speed of melting the raw materials is moderate. It is only suitable for virgin PP and PE pellets and the quality of the produced plastic corrugated boards is average. However, the control of a single screw extruder is relatively simple, and the cost of the equipment is low as well as the energy consumption.

The twin-screw extruder has two screws that can cooperate with each other for stirring, which has a strong mixing capacity. It is suitable for the mixing of various functional materials. The speed of melting raw materials is fast and the efficiency is high. Both virgin materials and recycled materials as well as various fillers can be mixed and extruded by the twin-screw extruder. The plastic corrugated plates produced have high precision, quality and stability. However, the operation of the twin-screw extruder is relatively complex, and the equipment cost and energy consumption are high.

The single-screw extruder is more suitable for customers who are sensitive to price. It has low operating costs and produces products of average quality. Products mainly using raw materials such as PP/PE are preferred to be processed by a single-screw extruder.

The twin-screw extruder is suitable for producing high-performance plastic corrugated board products, such as those with UV resistance, anti-static properties, and flame retardancy. If the customer has high requirements for the quality of the product or desires more performance from the plastic corrugated sheet, it would be best for the factory to use a twin-screw extruder to produce the product.

Suzhou Huiyuan Plastic Products Co., Ltd. has multiple single-screw and twin-screw extrusion production lines. It can provide customized solutions according to customer requirements.

If the product the customer desires is the standard PP plastic corrugated board, then Suzhou Huiyuan Plastic Products Co., Ltd. will use a single-screw extruder for production. This way, the cost is lower and the customer's quotation is also lower, saving the customer's expenses.

However, if the customer requires custom-made plastic corrugated sheets, Suzhou Huiyuan Plastic Products Co., Ltd. will use a twin-screw extruder. The use of a twin-screw extruder enables the production of the products to be more precise, reduces the defect rate, and ensures the functionality and stability of the products.

Although the hollow board may seem simple, it actually involves complex production processes and knowledge of materials science. Choosing the right extrusion method not only enhances the product performance but also offers customers a higher cost-effectiveness. Huiyuan Plastics will use professional equipment and 17 years of experience to tailor each hollow board to your needs, meeting the diverse industrial requirements.

For more information, please visit our official website: https://www.huiyuansjplastic.com/

For business cooperation, please contact: hy331@huiyuansj.cn

By continuing to use the site you agree to our privacy policy Terms and Conditions.