What is plastic corrugated sheet? A detailed introduction to hollow board

Plastic corrugated sheet, also known as plastic hollow sheet, is a double-layer hollow structure board made from PP or PE as raw materials. Due to its various excellent properties, it is widely used in various industries.

Ⅰ.The definition of plastic corrugated sheet

The plastic corrugated sheet is formed by extrusion process. The middle of the sheet is a cavity structure, and the upper and lower layers are supported by vertical ribs to form a stable grid. Its unique structure endows it with the physical properties of being lightweight and high-strength, making it highly suitable for scenarios that require both high-strength and lightweight materials.

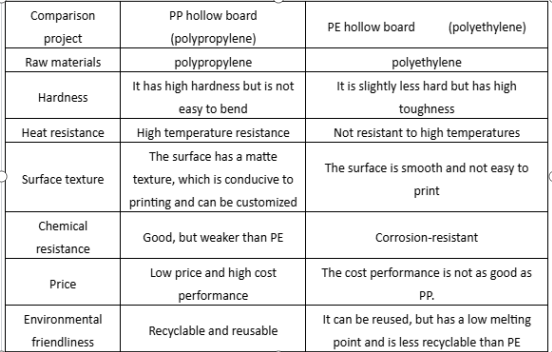

Ⅱ.Material comparison of plastic corrugated sheet

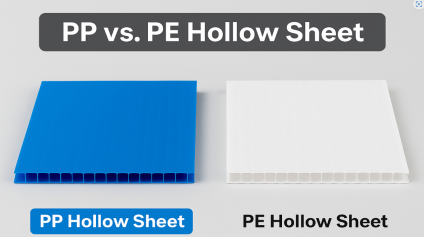

At present, in the market, there are mainly two raw materials for hollow sheets: one is PP (polypropylene), and the other is PE (polyethylene). Although both of them are raw materials for plastics, there are still some differences in their performance and application scenarios.

PP hollow board is the most common material in industrial packaging, which is light, hard and easy to process. PE hollow board, on the other hand, is suitable for application scenarios with special requirements for flexibility and corrosion resistance.

Ⅲ.The characteristics of plastic corrugated sheets

1. Hollow double-layer structure

It can significantly reduce weight while ensuring product strength

2. The thickness and weight of the sheet can be customized

Most plastic corrugated sheets require a thickness of 2 to 10mm. Factories can produce products of different thicknesses according to customers' demands and can also adjust the weight of the boards to make them harder.

3. It can be processed and treated by available techniques

Many customers want to purchase hollow boards and process the boards instead of using them directly. At this time, some processes may be used to process the boards. Due to its excellent physical properties, hollow boards can be cut, hot-pressed, bent and undergo more processes to turn them into the final products that customers desire.

Ⅳ.The advantages of plastic corrugated sheets

1. Light in weight and high in strength

Due to the hollowed-out nature in the middle of the hollow board, the overall weight of the board is relatively light. However, because the middle part has support, the board has high hardness and is suitable for use as a protective material.

2. Waterproof, moisture-proof and corrosion-resistant

The raw materials of hollow board are polypropylene or polyethylene, plastic materials. It is waterproof, moisture-proof and corrosion-resistant, and can be used in high-humidity or highly corrosive environments. This is one of the reasons why some materials cannot replace it.

3. Recyclable, environmentally friendly and non-toxic

Hollow board can be recycled and reused for other purposes, meeting contemporary environmental protection standards. Moreover, hollow board made of PP is non-toxic and can be used in high-demand industries, such as the food industry.

4. Low cost and strong customization

The cost of the sheets material is low, and the plastic is highly malleable. It can be processed according to customer requirements and eventually become the products that customers need.

Ⅴ.The main application fields of plastic corrugated plates

1. Packaging industry

(1) Turnover box

When it comes to logistics turnover, turnover boxes are needed to load products, thus facilitating more efficient product transportation. At this point, logistics turnover boxes made of hollow boards are an excellent choice. The turnover boxes made of hollow board are lightweight and can be customized in size according to customer requirements, thus achieving the effect of transporting products.

(2) Inner lining partition

When packaging products, if you want to use partition boards inside the storage container to better fix the products, hollow board knife cards can well meet this requirement. A turnover box combined with internal partitions can better store the products and reduce the product damage rate. It is currently widely used in the automotive parts industry.

2. Advertising industry

(1) Advertising board

In many regions, some printing companies use hollow boards for printing. This is because the surface of hollow boards can be electrohaled, and after electrohaling, it has excellent adhesion to pigments, making it an excellent material for printing.

(2) Display stand

When many large supermarkets display snacks, they often use hollow boards as display stands to promote their products, which can also achieve a very good advertising effect.

3. Construction industry

Floor protection

In the construction industry, a protective board is often laid on the ground during construction to ensure that the floor is not damaged. At this time, hollow board is an excellent choice. Hollow board is low in price, light in weight and high in hardness, making it very suitable for use as a floor protection board.

4. Agricultural industry

(1) Seedling box

In the agricultural industry, hollow boards are made into a box for cultivating plant seedlings, as shown in the picture.

(2) Sapling protection

In some countries, local people often wrap a layer of boards around the outside of the saplings for protection in order to make them grow better. This is sapling protection.

Ⅵ.How to choose the right hollow board

1.Choose from thickness and weight

(1) Thickness

For sheet products, most customers have strict requirements for the thickness of the products. Therefore, when choosing hollow boards, thickness is a very important selection criterion.

(2) Weight

Among sheet materials, there is a relatively specialized thickness measurement index called gram weight, which is the weight per square meter. When explained in the context of hollow board, it refers to the weight of one square meter of hollow board in grams. Users can purchase hollow boards of corresponding weight from suppliers according to their own needs. Generally speaking, the higher the weight, the harder the board.

2. Select from physical properties

(1)Anti-static

Some users hope to use hollow boards in the electronics industry. At this time, they may hope that the boards are anti-static so that they can be used in electronic products. At this point, the factory can add anti-static raw materials to the hollow boards to make them into anti-static hollow boards, which can meet the needs of users.

(2) Flame retardant treatment

Some users also hope that the hollow board can be made flame-retardant. At this time, the factory can also add flame-retardant raw materials during production to produce flame-retardant hollow boards, and according to the requirements of the users, make flame-retardant hollow boards of three grades: V0, V1, and V2.

To sum up, plastic corrugated board is a widely used type of board in various industries. If you have the need to purchase plastic corrugated board, you can consult Suzhou Huiyuan Plastic Products Co., LTD. This company was established in 2008 and specializes in the production of plastic hollow board. It has rich production and sales experience and is sure to provide you with satisfactory products.

By continuing to use the site you agree to our privacy policy Terms and Conditions.