©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

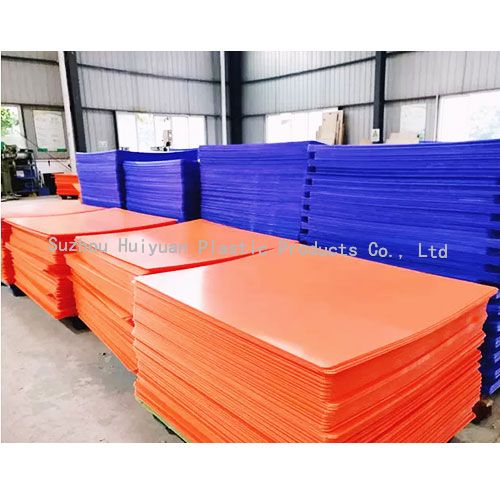

Corrugated plastic layer pads have become an essential component in modern packaging solutions, offering protection, stability, and versatility. These pads are widely used in industries such as food and beverage, electronics, pharmaceuticals, and logistics. They provide a lightweight yet durable solution for separating, cushioning, and stacking products during storage and transportation. In this article, we will explore the different types of corrugated plastic layer pads, their characteristics, applications, and benefits.

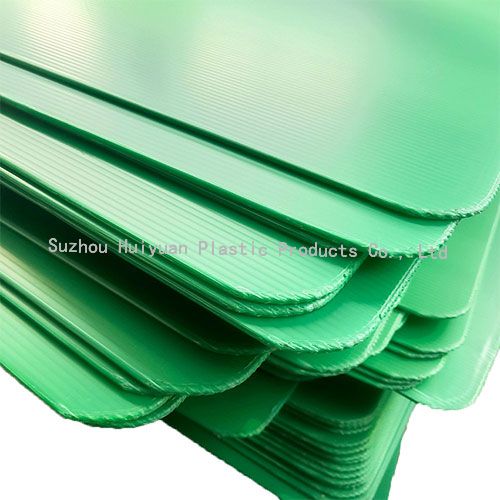

A corrugated plastic layer pad is a flat sheet made of corrugated polypropylene (PP) or polyethylene (PE) designed to provide structural support between layers of products. Unlike traditional cardboard layer pads, corrugated plastic pads are water-resistant, reusable, and more durable. They are available in various thicknesses, sizes, and designs to suit different packaging requirements.

The corrugated structure gives the pad enhanced strength and flexibility, allowing it to absorb shocks and prevent product damage. This makes them ideal for industries where product integrity is crucial during shipping and handling.

Using corrugated plastic layer pads offers several benefits:

Durability: Resistant to water, chemicals, and moisture, ensuring longevity.

Reusability: Can be reused multiple times, reducing packaging costs.

Lightweight: Reduces shipping weight compared to wooden or solid plastic alternatives.

Customizability: Available in different sizes, thicknesses, and colors for specific needs.

Eco-friendly: Many are recyclable and contribute to sustainable packaging solutions.

Shock Absorption: Protects fragile products during transportation.

Corrugated plastic layer pads come in different types depending on their material composition, structure, and intended application. Here are the most common types:

Single-wall pads are the most basic type of corrugated plastic layer pad. They consist of one corrugated sheet sandwiched between two flat sheets. This design provides adequate strength for lightweight or moderately heavy products.

Features:

Lightweight and flexible

Economical and cost-effective

Suitable for medium-duty applications

Applications:

Food and beverage packaging

Small electronics packaging

Cosmetic product layers

Double-wall corrugated plastic layer pads have two layers of corrugation, providing enhanced strength and rigidity. These pads are ideal for heavy or fragile items that require extra protection during stacking and transportation.

Features:

High load-bearing capacity

Excellent shock absorption

Durable for repeated use

Applications:

Bottled beverages

Glass products

Industrial components

Perforated corrugated plastic layer pads include pre-cut holes or slots to allow better ventilation and air circulation. This type is particularly useful for perishable goods or products sensitive to moisture and temperature changes.

Features:

Enhanced airflow for products

Lightweight design

Reduces condensation and spoilage

Applications:

Fresh produce packaging

Frozen foods

Pharmaceuticals requiring temperature control

Anti-slip layer pads have a textured surface or special coating to prevent products from sliding during stacking and transport. These pads are widely used in industries where stability is critical.

Features:

Reduces product movement

Enhances stacking stability

Prevents damage during handling

Applications:

Bottled liquids

Heavy equipment parts

Glass or ceramic items

Many manufacturers offer fully customized corrugated plastic layer pads to meet specific client requirements. Customization can include size, thickness, color, surface texture, and even printed logos.

Features:

Tailored dimensions for specific products

Branding opportunities through printed designs

Enhanced protective features

Applications:

Corporate packaging solutions

Fragile electronic items

Specialty product logistics

Corrugated plastic layer pads are mainly made from polypropylene (PP) or polyethylene (PE). Both materials offer unique advantages:

| Material | Features | Typical Applications |

|---|---|---|

| Polypropylene (PP) | Rigid, durable, chemical-resistant | Food packaging, industrial products, pharmaceuticals |

| Polyethylene (PE) | Flexible, lightweight, impact-resistant | Fresh produce, electronics, cold storage logistics |

The choice of material depends on the product type, shipping environment, and desired durability. For instance, PP is more suited for heavy-duty applications, while PE is ideal for lightweight and flexible packaging needs.

Corrugated plastic layer pads are available in various thicknesses, usually ranging from 2 mm to 6 mm, and standard sheet sizes such as 1200 mm x 800 mm, 1000 mm x 1000 mm, or custom sizes. Thicker pads are used for heavier products, while thinner ones are suitable for lightweight goods.

Factors to Consider When Selecting Thickness:

Product weight

Stacking height

Environmental conditions (humidity, temperature)

Reusability requirements

In the food and beverage sector, corrugated plastic layer pads are commonly used to separate layers of bottles, cans, and packaged goods. Their water-resistant properties prevent moisture damage, and their durability ensures safe transport.

Electronics require careful handling due to their fragility. Anti-slip or double-wall layer pads provide stability and cushioning, preventing movement and potential damage.

Pharmaceutical products often require controlled environments. Perforated and moisture-resistant corrugated plastic layer pads ensure proper ventilation and protection against humidity, extending shelf life.

The growth of e-commerce has increased the demand for efficient packaging solutions. Corrugated plastic layer pads are ideal for stacking, protecting, and organizing products for shipment.

Heavy machinery parts, glassware, and other industrial items benefit from double-wall or custom layer pads that provide superior strength and protection during storage and transport.

Selecting the appropriate corrugated plastic layer pad depends on several factors:

Weight of Products: Heavier products require thicker or double-wall pads.

Stacking Requirements: Determine how high the products will be stacked and select pads that can withstand the load.

Environmental Conditions: Consider exposure to moisture, chemicals, or extreme temperatures.

Product Sensitivity: Fragile items need anti-slip or perforated designs for added protection.

Reusability and Sustainability: For long-term use, choose durable, recyclable materials like PP or PE.

Corrugated plastic layer pads are versatile, durable, and essential in modern packaging solutions. They provide superior protection, stability, and efficiency across various industries. From single-wall pads for lightweight goods to customized double-wall or perforated pads for heavy or delicate items, there is a type suitable for every packaging need. By selecting the right pad based on product type, weight, and environmental conditions, businesses can ensure safe transport, reduce damage, and enhance sustainability.

Understanding the types and applications of corrugated plastic layer pads can help companies optimize their packaging strategy, save costs, and improve overall supply chain efficiency.

By continuing to use the site you agree to our privacy policy Terms and Conditions.