©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

In today’s fast-paced logistics and manufacturing industries, packaging plays a vital role in protecting products during transportation and storage. Among various packaging solutions, custom corrugated honeycomb PP boxes stand out as a modern, lightweight, and highly durable option. Whether you are in the automotive, electronics, food, or e-commerce sector, these boxes offer efficiency, strength, and eco-friendliness. This article explores everything you need to know about custom corrugated honeycomb PP boxes, including their features, benefits, applications, and why they are an excellent choice for businesses seeking reliable packaging.

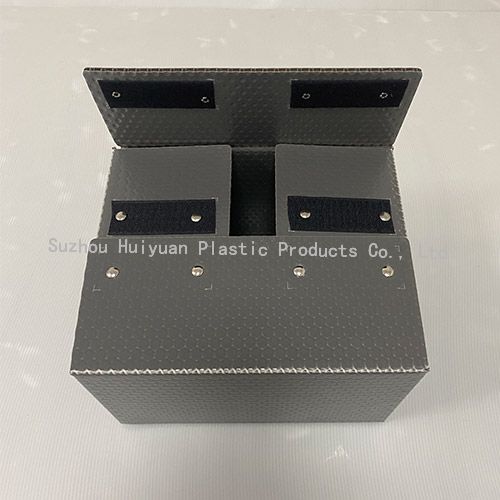

When businesses choose custom corrugated honeycomb PP boxes, they benefit from several key features that distinguish them from standard packaging:

Lightweight but strong – The honeycomb design distributes stress evenly, offering high compression strength while remaining easy to handle.

Customizable – Size, shape, thickness, and even printing can be tailored to meet a company’s requirements.

Waterproof and chemical-resistant – Unlike paper-based packaging, PP honeycomb boxes resist moisture, oils, and many chemicals.

Reusable and recyclable – Polypropylene is eco-friendly, reducing waste and promoting circular use.

Shock and vibration absorption – The honeycomb core structure helps protect fragile products during long-distance shipping.

Cost-effective – Longer lifespan compared to traditional corrugated cardboard boxes.

Businesses increasingly turn to custom corrugated honeycomb PP boxes because they combine practicality and sustainability. Some advantages include:

The honeycomb structure provides excellent cushioning, reducing the risk of damage to goods during transportation. For industries like electronics or automotive, where components are highly sensitive, this is invaluable.

Custom manufacturing ensures boxes fit perfectly with product dimensions, eliminating wasted space and lowering shipping costs. Businesses can also request partitions or inserts for added organization.

PP honeycomb boxes can be printed with company logos, handling instructions, or barcodes. This turns packaging into a branding tool while improving traceability in logistics.

Sustainability is a growing concern. These boxes are 100% recyclable and reusable, aligning with corporate social responsibility (CSR) goals and green supply chain practices.

While initial investment may be higher than traditional cardboard, the durability and reusability of honeycomb PP boxes reduce replacement frequency and total costs over time.

Because of their versatility, these boxes are widely used across industries:

Automotive Industry – Packaging for spare parts, engines, and delicate components.

Electronics – Ideal for laptops, smartphones, and fragile circuit boards.

E-commerce & Retail – Safe packaging for bulk goods, clothing, or high-value products.

Food & Beverage – Packaging that withstands cold storage or moisture environments.

Pharmaceuticals – Hygienic, sturdy containers for medical devices and supplies.

Logistics & Warehousing – Durable storage containers that can be reused multiple times.

To understand the advantages more clearly, let’s compare custom corrugated honeycomb PP boxes with traditional corrugated cardboard boxes:

| Feature | Honeycomb PP Boxes | Traditional Corrugated Cardboard Boxes |

|---|---|---|

| Strength | High compression strength, durable | Weaker under heavy loads |

| Weight | Lightweight | Lightweight |

| Moisture Resistance | Waterproof and chemical-resistant | Absorbs water, weakens |

| Reusability | Long lifespan, reusable many times | Limited reusability |

| Eco-Friendliness | 100% recyclable | Recyclable but shorter lifecycle |

| Cost | Higher initial cost but cost-effective long-term | Lower initial cost but higher replacement frequency |

| Customization | Highly customizable | Customizable but less durable |

Clearly, PP honeycomb boxes offer a more sustainable and protective option for long-term logistics strategies.

One of the biggest advantages of these boxes is customization. Depending on your needs, manufacturers can adjust:

Size and Dimensions – Designed to fit unique product sizes and reduce void space.

Thickness – Different sheet thicknesses for varying load capacities.

Colors – Available in standard or brand-specific colors.

Printing – Custom logos, graphics, barcodes, or QR codes.

Structural Additions – Handles, dividers, inserts, or reinforced edges for extra protection.

This customization makes them ideal for companies that want packaging aligned with both functional and branding goals.

Several trends are driving the adoption of custom corrugated honeycomb PP boxes:

Sustainability Requirements – Companies are pressured to reduce single-use packaging.

E-commerce Growth – The need for strong yet lightweight packaging has skyrocketed with online retail.

Global Supply Chains – Products often travel thousands of kilometers; reliable packaging is essential.

Regulatory Compliance – Many industries (e.g., food and pharma) require moisture-resistant and hygienic packaging.

By adopting PP honeycomb packaging, businesses future-proof their logistics and enhance efficiency.

The price of these boxes depends on several variables:

Dimensions and thickness – Larger, thicker boxes cost more.

Customization level – Printing, handles, or inserts add to cost.

Order quantity – Bulk orders usually reduce per-unit cost.

Material grade – Different grades of PP sheets affect durability and price.

Transportation and logistics – Costs vary based on shipping distance and handling.

Although they may be more expensive upfront, the durability and reusability lead to long-term savings.

To maximize their benefits, businesses should follow some best practices:

Choose the correct thickness for your load-bearing needs.

Design custom inserts for fragile products to reduce damage.

Reuse boxes as many times as possible before recycling.

Train staff to handle boxes properly to extend their lifespan.

Work with a reliable manufacturer for consistent quality.

In modern supply chains, packaging is no longer just about containment—it’s about protection, efficiency, sustainability, and branding. Custom corrugated honeycomb PP boxes check all these boxes. They provide superior strength, reusability, and customization options compared to traditional packaging.

By investing in these boxes, companies can reduce costs in the long term, improve product safety during transit, and align with eco-friendly goals. Whether you are shipping sensitive electronics, heavy auto parts, or everyday retail goods, honeycomb PP boxes provide a versatile solution.

If you are looking to upgrade your packaging strategy, exploring custom corrugated honeycomb PP boxes could be the key to enhancing your logistics efficiency while demonstrating a commitment to sustainability.

By continuing to use the site you agree to our privacy policy Terms and Conditions.