©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

In the world of lightweight and versatile materials, the corrugated plastic board has emerged as a popular solution for a wide range of applications. From advertising and packaging to industrial use, this material offers durability, flexibility, and cost-effectiveness. In this article, we will explore what a corrugated plastic board is, its composition, various applications, advantages, and considerations for use. Additionally, we will touch upon related items such as corrugated plastic sign board and corrugated sign board, helping you understand the full potential of this versatile material.

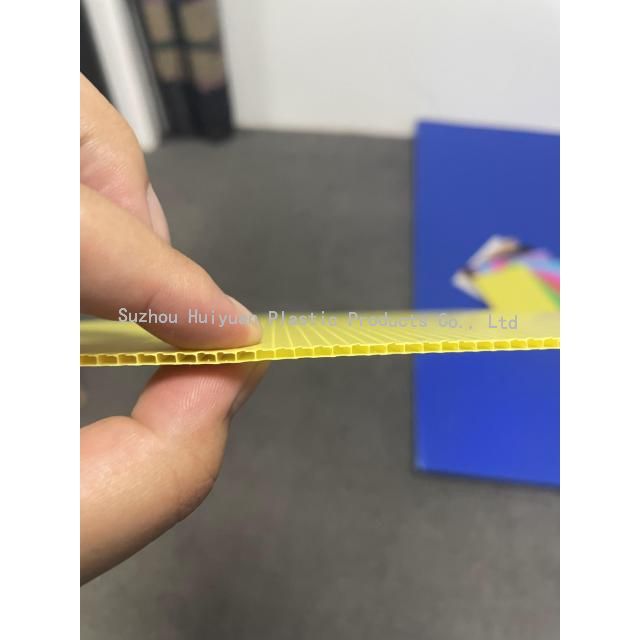

A corrugated plastic board is a type of lightweight, hollow sheet made from polypropylene (PP) or polyethylene (PE) material. The board is designed with a fluted or corrugated structure, which provides strength while keeping the weight minimal. Unlike solid plastic sheets, the hollow structure of the corrugated board makes it ideal for applications requiring rigidity without adding bulk.

The fluted design typically consists of parallel ribs or channels that run through the sheet, creating a strong internal support structure. This design allows the board to withstand bending and pressure, making it suitable for both indoor and outdoor applications. The lightweight nature of the material also simplifies transportation and installation.

In essence, the corrugated plastic board combines the benefits of plastic durability with a cardboard-like structure, offering a versatile alternative to paper, cardboard, and solid plastic sheets.

The majority of corrugated plastic boards are made from polypropylene (PP), a thermoplastic polymer known for its chemical resistance, durability, and lightweight properties. Some boards are made from polyethylene (PE), which shares similar properties but can offer additional flexibility.

The manufacturing process involves extrusion, where melted plastic is pushed through a mold to form the characteristic fluted structure. After cooling, the sheet is cut into desired sizes and thicknesses. The most common thicknesses range from 2 mm to 10 mm, with larger sheets available for industrial or advertising purposes.

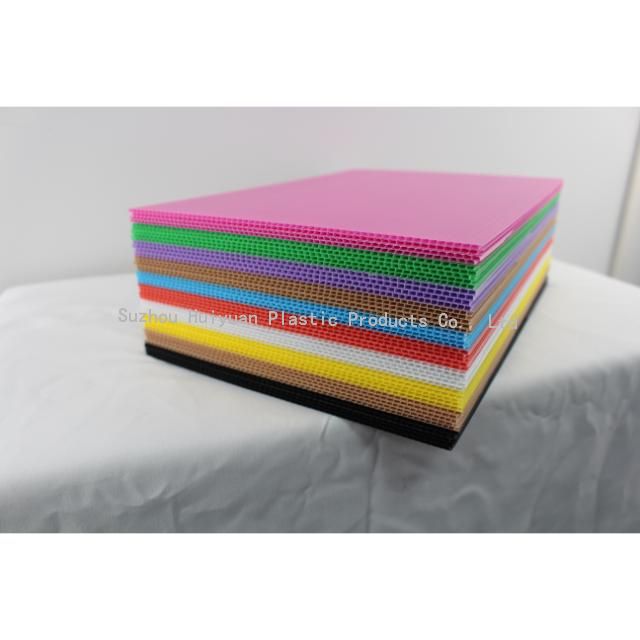

In addition to the base material, corrugated plastic boards can be produced in various colors, including white, black, and transparent options. Colored boards are particularly popular for signage, promotional displays, and packaging applications, where visibility and aesthetics are important.

Corrugated plastic boards are available in several types depending on their intended use. Here are some of the most common variations:

These are the most widely used sheets, suitable for general packaging, protection, and display applications. Standard boards are lightweight, affordable, and easy to cut or shape, making them a versatile option for many industries.

The corrugated plastic sign board is specifically designed for signage applications. These boards often feature smooth surfaces suitable for printing, painting, or mounting vinyl graphics. They are commonly used for real estate signs, political campaign signs, event announcements, and directional signs. Their durability ensures that outdoor signs remain intact even in harsh weather conditions.

Some corrugated plastic boards are manufactured with additional features, such as UV resistance, fire retardancy, or anti-static properties. These specialized boards cater to specific industries such as electronics, construction, or chemical packaging, where standard boards may not provide adequate performance.

The corrugated plastic board is versatile and used across many industries.

Its lightweight yet strong structure makes it ideal for reusable boxes, protective layers, and shipping fragile goods.

Corrugated plastic sign boards and corrugated sign boards are perfect for temporary or semi-permanent signs and outdoor promotions.

It protects floors, walls, and surfaces during renovation and is used for partitions and packaging inserts.

Lightweight and easy to cut, it’s great for models, displays, hobby projects, and custom signs.

The corrugated plastic board offers several advantages that make it a practical choice for many applications:

Despite being lightweight, corrugated plastic boards are highly durable. The fluted structure provides strength and resistance to bending, making them capable of supporting heavy loads relative to their weight.

Most corrugated plastic boards are resistant to water, UV rays, and harsh weather conditions. This property makes them ideal for outdoor signs, protective packaging, and temporary structures exposed to the elements.

Compared to solid plastic sheets or metal panels, corrugated plastic boards are more affordable. They offer a balance of performance and price, especially when used for temporary or disposable applications.

Corrugated plastic boards are environmentally friendly because they are reusable and recyclable. Businesses can use them multiple times for packaging or signage, reducing waste. At the end of their life cycle, they can be recycled into new polypropylene products.

These boards can be easily cut, folded, drilled, or glued, allowing for quick customization. This flexibility makes them suitable for various creative, industrial, and commercial projects.

While corrugated plastic boards are similar in appearance to cardboard, they provide distinct advantages over paper-based materials:

Moisture Resistance: Unlike cardboard, corrugated plastic boards do not absorb water, preventing warping and weakening.

Durability: They are stronger and more resistant to tearing or crushing.

Longevity: Suitable for both indoor and outdoor applications, unlike cardboard, which degrades quickly outside.

Compared to solid plastic sheets, corrugated plastic boards are lighter and more cost-effective while still providing structural integrity. This makes them an ideal choice when balancing strength, weight, and price.

In summary, the corrugated plastic board is a lightweight, durable, and versatile material with a wide range of applications. From packaging to signage, construction to creative projects, it offers practical solutions where traditional materials may fall short. Variations such as the corrugated plastic sign board and corrugated sign board demonstrate the material’s adaptability for advertising and communication purposes.

Whether you are a business looking for cost-effective signage, an industrial manufacturer seeking protective packaging, or a DIY enthusiast exploring creative possibilities, corrugated plastic boards offer unmatched versatility and convenience. With their durability, reusability, and ease of customization, they are poised to remain a staple in both commercial and personal applications for years to come.

By continuing to use the site you agree to our privacy policy Terms and Conditions.