©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

In today’s fast-paced logistics and packaging industry, businesses are constantly seeking solutions that are durable, versatile, and cost-effective. One product that has gained significant attention in recent years is the PP sheet box, a type of container made from polypropylene (PP) sheets. Known for its exceptional strength, lightweight design, and versatility, the PP sheet box has become a staple in warehouses, transportation, and industrial applications. In this article, we will explore the main advantages of PP sheet boxes, their practical applications, and why they are quickly replacing traditional packaging options.

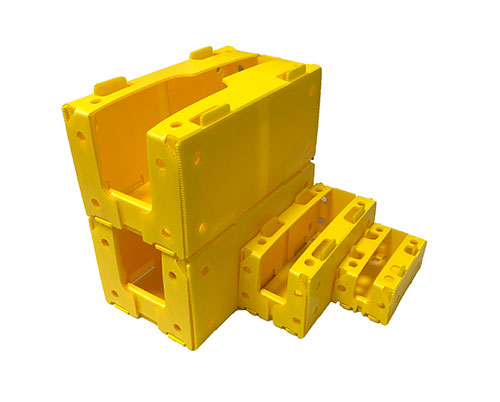

A PP sheet box is a container made from polypropylene sheets, which are thermoplastic polymer materials. These boxes are engineered for robustness, chemical resistance, and long-term usability. Unlike traditional cardboard or wooden boxes, PP sheet boxes can withstand moisture, extreme temperatures, and repeated handling without deforming. They are commonly used in industries that demand hygienic, strong, and reusable storage solutions, such as food processing, electronics, pharmaceuticals, and automotive sectors.

PP sheet boxes are available in various sizes, thicknesses, and colors. They can be custom-designed to meet specific requirements, including stackability, foldability, or the inclusion of handles and lids. Their versatility makes them suitable for both small-scale storage needs and large-scale logistics operations.

One of the primary advantages of PP sheet boxes is their durability. Polypropylene is a robust plastic material that can endure heavy loads without cracking or breaking. This makes PP sheet boxes ideal for transporting goods over long distances or handling heavy industrial components. Unlike cardboard boxes, which may weaken when wet or under continuous pressure, PP sheet boxes maintain their structural integrity, ensuring safe storage and transportation.

Despite their strength, PP sheet boxes are remarkably lightweight. This makes handling, lifting, and stacking much easier compared to traditional materials like wood or metal. Lightweight packaging reduces shipping costs and allows for more efficient warehouse operations. Additionally, workers can manage these boxes with minimal effort, reducing the risk of injuries related to heavy lifting.

PP sheet boxes are inherently waterproof and resistant to a wide range of chemicals, including acids, bases, and oils. This feature makes them particularly valuable in industries such as food and beverage, pharmaceuticals, and chemicals, where contamination or moisture exposure can compromise the integrity of products. Unlike cardboard or paperboard, PP sheet boxes do not absorb water or chemicals, ensuring long-term usability.

Sustainability is becoming increasingly important in modern business practices. PP sheet boxes are reusable and recyclable, making them an environmentally friendly packaging solution. They can be used multiple times without losing their strength, reducing the need for disposable packaging materials. Many companies now adopt PP sheet boxes as part of their green initiatives, reducing waste and promoting sustainability in their operations.

Another advantage of PP sheet boxes is their high level of customization. PP box manufacturers can produce boxes in different sizes, thicknesses, and colors to meet specific business needs. Additionally, PP sheet boxes can be designed with unique features, such as interlocking lids, folding panels, or perforated sides, enhancing their functionality. This flexibility makes them suitable for a wide range of applications, from small component storage to large-scale transportation containers.

While the initial cost of a PP sheet box may be higher than cardboard or simple plastic alternatives, their durability and reusability make them cost-effective in the long run. Companies benefit from reduced replacement costs, lower shipping damage, and minimized waste. Over time, investing in PP sheet boxes can result in substantial savings, especially for businesses involved in frequent shipping or heavy-duty storage.

PP sheet boxes are widely used in industrial and manufacturing environments. They are perfect for storing raw materials, semi-finished components, and finished products. Their durability and chemical resistance make them suitable for factories, warehouses, and production lines where handling and transportation are frequent.

In the food and beverage sector, hygiene and safety are critical. PP sheet boxes are non-toxic, easy to clean, and resistant to moisture, making them ideal for storing and transporting fresh produce, dairy products, seafood, and other perishable items. Their waterproof and chemical-resistant properties help maintain product quality while minimizing contamination risks.

Pharmaceutical companies require storage solutions that ensure product safety and cleanliness. PP sheet boxes are resistant to chemicals and easy to sanitize, making them suitable for storing medical supplies, drugs, and laboratory equipment. Their stackable design also maximizes storage space in cleanrooms and laboratories.

In logistics, the strength and stackability of PP sheet boxes improve operational efficiency. These boxes can withstand repeated loading and unloading without deformation, reducing the risk of product damage during transportation. Their lightweight nature also helps optimize shipping costs and fuel consumption.

PP sheet boxes are used extensively in the electronics and automotive industries to store delicate components and parts. The boxes’ sturdy construction protects sensitive items such as circuit boards, sensors, and automotive parts from physical damage, dust, and moisture. Customizable interiors, such as foam inserts, can further enhance protection.

E-commerce businesses benefit from the durability and reusability of PP sheet boxes. They provide secure packaging for high-value or fragile items, reduce return damages, and enhance brand image through professional, clean packaging. Retailers also appreciate the aesthetic appeal of these boxes for display purposes.

In summary, PP sheet boxes offer a combination of strength, lightweight design, chemical resistance, reusability, and versatility that few other packaging materials can match. From industrial storage to food processing, pharmaceuticals, logistics, electronics, and retail, their applications are wide-ranging. Choosing PP sheet boxes not only ensures the safety and integrity of products but also contributes to sustainable business practices.

As industries continue to prioritize efficiency, hygiene, and sustainability, the popularity of PP sheet boxes is set to grow. Investing in high-quality PP sheet boxes is a smart decision for businesses seeking durable, cost-effective, and eco-friendly packaging solutions.

By understanding the advantages and applications of PP sheet boxes, companies can make informed decisions to optimize their storage, transportation, and overall operational efficiency. Whether you are running a factory, warehouse, or e-commerce business, PP sheet boxes provide a reliable, long-term solution for modern packaging needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.