©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

In modern packaging, storage, and logistics, PP carton products have become one of the most efficient, durable, and cost-effective solutions. Whether used for shipping delicate electronics, storing industrial components, organizing warehouse items, or packaging agricultural goods, PP carton box and PP carton sheets offer superior performance compared to traditional paper cartons. Their waterproof nature, lightweight design, and long service life make them an excellent choice for businesses looking to improve packaging efficiency and reduce operational costs.

This comprehensive guide will walk you through everything you need to know about PP carton materials—what they are, their benefits, how PP carton box solutions are made, common applications, customization options, and how to choose the right PP carton sheets for your needs.

A PP carton is a packaging product made from polypropylene (PP), a thermoplastic polymer known for its strength, flexibility, and chemical resistance. Unlike traditional cardboard boxes that are made from paper fibres, PP carton box products use extruded PP sheets—often referred to as PP corrugated sheets or PP hollow sheets.

These sheets feature a unique three-layer structure:

A smooth outer layer

A ribbed inner layer

Another smooth surface

This construction gives PP carton sheets outstanding rigidity while maintaining lightweight properties. As a result, PP cartons can withstand external pressure, bending, and repeated handling without deformation.

When comparing PP cartons with regular carton boxes, the advantages become clear. Here are the most important benefits:

Paper cartons weaken and lose shape when exposed to moisture. In contrast, PP carton box products are fully waterproof. They absorb zero moisture and maintain structural integrity even in damp, humid, or rainy environments.

PP carton sheets have excellent impact resistance. They can withstand rough handling, vibration, and stacking without crushing—making them ideal for logistics and industrial shipping.

A PP carton can be used dozens or even hundreds of times. This makes them more economical in long-term operations and supports eco-friendly business practices.

PP is resistant to oils, acids, solvents, and various chemicals. Industries like electronics, agriculture, automotive, and medical packaging prefer PP cartons due to this advantage.

Despite their strength, PP carton sheets weigh much less than wooden boxes or thick cardboard. This reduces transportation costs and improves handling efficiency.

PP carton box products can be washed and disinfected, making them suitable for food, medical devices, and pharmaceutical logistics.

PP material can be recycled into new plastic products, helping reduce environmental waste.

PP carton sheets are produced through an extrusion process:

PP pellets are heated and melted.

The molten material passes through a shaped die.

It forms a lightweight, hollow-core sheet.

The sheet is cooled and cut into required dimensions.

The finished PP carton sheets can then be printed, laminated, die-cut, stitched, ultrasonic welded, or riveted to produce various PP carton box types.

Common thicknesses include 2mm, 3mm, 4mm, 5mm, and 6mm, depending on the strength requirements.

PP cartons can be customized into different structures to meet different industry demands. Popular types include:

These boxes are lightweight, collapsible, and easy to store. They save warehouse space and reduce shipping volume.

Common in warehouses and distribution centers, they protect products from dust and moisture.

Ventilation holes allow air circulation, keeping produce fresh during transportation.

Internal partitions made from PP carton sheets protect fragile or small components from collisions.

Designed for industrial use, providing extra strength for automotive parts, electronics, and machinery components.

Electrostatic-dissipative PP carton for electronic chips, PCBs, sensors, and other static-sensitive components.

Printed PP sheets can be turned into packaging with excellent branding visibility for retail and promotional use.

PP carton sheets and boxes are widely used in many industries due to their versatility. Here are the most common applications:

PP carton boxes protect goods during shipping and reduce breakage rates.

Used for packaging and transporting vegetables, fruits, seedlings, and fertilizers.

PP carton sheets are used to create anti-static compartments for sensitive electronic components.

Suitable for packaging car parts, including clips, wiring harnesses, sensors, and interior accessories.

Durable and attractive PP carton box packaging helps ensure safe delivery of products.

Ideal for sterile, moisture-free storage and transportation.

PP carton sheets are used as temporary floor protection, wall protection, and partition panels on job sites.

PP carton sheets can be made into waterproof document boxes, file organizers, and office storage solutions.

Thicker PP carton sheets (5mm or 6mm) offer higher load capacity. Thinner sheets (2mm–3mm) are suitable for lightweight packaging.

Smooth

Matte

Corona-treated for printing

Laminated

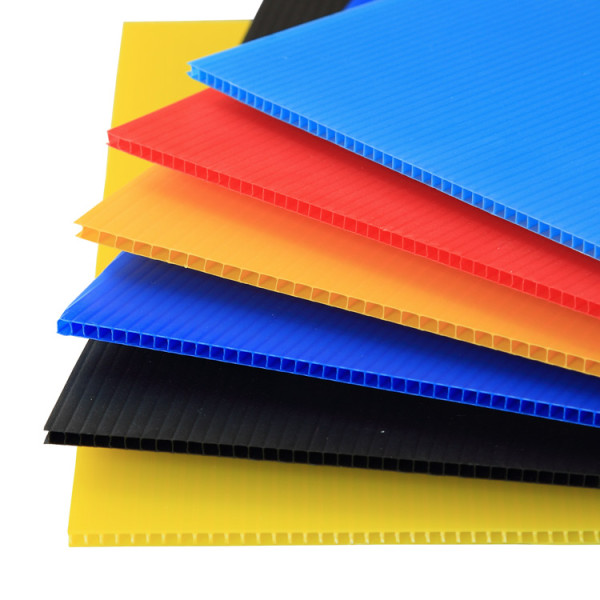

PP carton sheets can be produced in any color, including blue, white, black, transparent, yellow, and custom Pantone shades.

Logos, handling symbols, barcodes, and product details can be printed directly on the PP carton box.

Here are factors to consider:

Heavier items require thicker PP carton sheets and a stronger box structure.

Outdoor transportation may require UV-resistant or water-resistant properties.

For long-term use, opt for reinforced edges, welded seams, and heavy-duty PP sheets.

ESD PP carton boxes may be necessary for electronics.

Fragile goods may require dividers, foam inserts, or custom PP partitions.

Thicker sheets cost more but offer greater durability and longer service life.

PP carton products—whether in the form of PP carton box or PP carton sheets—have become essential in modern packaging and logistics. Their lightweight design, excellent durability, waterproof performance, reusability, and wide customization possibilities make them suitable for almost every industry.

If your business needs reliable, long-lasting, and eco-friendly packaging solutions, PP cartons are worth considering. They not only protect your products effectively but also help reduce long-term operational costs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.