©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

In any warehouse operation, packaging is far more than just a finishing step before delivery. The choice of warehouse packing boxes directly affects product safety, space utilization, cost efficiency, and even the overall flow of logistics. For businesses of all sizes—from e-commerce retailers to large-scale distribution centers—choosing the right packing solution is essential to maintaining a competitive edge.

This comprehensive guide will walk you through how to select the best warehouse packing boxes for your specific needs. We will cover materials, size considerations, durability, costs, and common mistakes to avoid, so that your warehouse packing process becomes smooth, professional, and efficient.

Many businesses underestimate the value of the humble box. In reality, warehouse packing boxes play multiple roles that impact your daily operations:

Protection of goods: Prevents breakage, dents, and contamination.

Optimization of space: Properly sized boxes stack neatly, saving warehouse space.

Efficiency in handling: Uniform boxes streamline picking, packing, and shipping processes.

Reduction of costs: Correct box selection reduces void fill material, lowers shipping weight, and minimizes returns.

Professional branding: Boxes with consistent design and printing strengthen your company image.

Without the right boxes, warehouses risk inefficient stacking, wasted space, and damaged goods, all of which increase operational costs.

The foundation of any packing solution lies in its material. The most common options include:

Corrugated cardboard: Lightweight, cost-effective, and durable enough for most shipping tasks. It is the industry standard for a wide range of warehouse applications.

Plastic boxes: Rigid, reusable, and long-lasting. Perfect for high-turnover warehouses or closed-loop supply chains.

Wooden crates: Suitable for industrial or heavy-duty products, machinery, or export goods requiring extra protection.

Metal boxes: Rare, but sometimes used for extremely heavy or sensitive goods that require secure containment.

Most warehouses will rely on corrugated cardboard, but for operations focused on sustainability or repeated handling, reusable plastic warehouse packing boxes may be a better long-term investment.

Size matters more than you think. Choosing boxes that are too big wastes storage and increases shipping costs due to excess dimensional weight. On the other hand, undersized boxes may not provide sufficient protection for the product.

When choosing warehouse packing boxes:

Measure your most common products and select standard box sizes that accommodate them.

Align box sizes with pallet dimensions for efficient stacking.

Avoid excessive empty space that requires too much filler material.

Standardizing sizes reduces complexity in inventory and ensures smoother warehouse operations.

Boxes are rated based on their ability to hold weight without collapsing. Corrugated cardboard, for example, comes in different wall thicknesses:

Single-wall boxes: Best for lightweight items like apparel, electronics accessories, or small parts.

Double-wall boxes: Designed for medium to heavy products such as books, automotive parts, or industrial equipment.

Triple-wall boxes: Extremely strong, suitable for bulky and heavy products.

Never ignore the strength rating of your warehouse packing boxes, as underestimating load capacity may result in collapsed stacks and damaged goods.

Durability is critical in a packing boxes warehouse environment. Boxes are constantly handled, moved, stacked, and sometimes reused. A weak box can fail after just one cycle.

If products are moved multiple times, consider stronger cardboard or plastic bins.

For items stored long-term, choose boxes resistant to humidity and wear.

For high-volume warehouses, reusable plastic crates can cut costs by lasting for years.

Durability also reduces the frequency of replacing boxes, which lowers long-term operational expenses.

Warehouses depend on vertical space as much as floor space. Well-designed boxes must:

Stack without collapsing.

Fit neatly onto pallets.

Optimize shelf use with standardized sizing.

Uniform warehouse packing boxes improve overall efficiency by minimizing wasted space and allowing smooth logistics flow from storage to shipping.

Budget is always a consideration, but focusing only on the cheapest option often leads to higher costs later. Instead, evaluate the total value:

Purchase price vs. longevity of the box.

Weight of the box, which affects shipping fees.

Reduction in product damages and customer returns.

Labor savings due to easier handling and stacking.

Sometimes, slightly more expensive but sturdier boxes provide better overall savings.

Some warehouses deal with products that need specialized box features:

Moisture-resistant boxes for perishable or pharmaceutical goods.

Anti-static packaging for electronics and sensitive components.

Temperature-resistant boxes for cold storage warehouses.

Branded boxes with logos for businesses that ship directly to customers.

Always consider whether your warehouse operations require these specialized packing boxes warehouse solutions.

Standard corrugated cardboard boxes – economical and versatile.

Heavy-duty double-wall boxes – for bulk and heavy shipments.

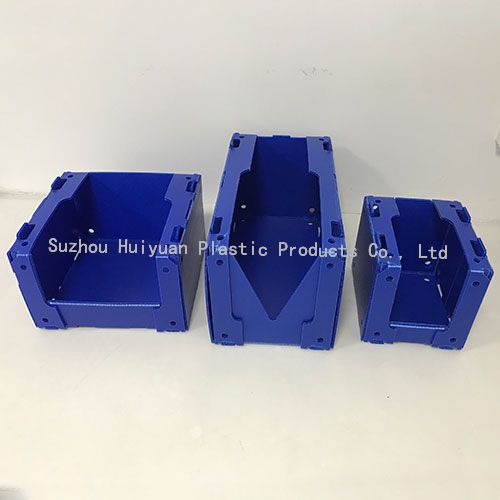

Foldable plastic crates – durable, stackable, and reusable.

Die-cut custom boxes – shaped to specific product requirements.

Storage totes with lids – ideal for long-term storage or fragile goods.

Export shipping boxes – designed for overseas transport with extra reinforcement.

Each category serves a unique purpose, and many warehouses use a mix of different types.

Standardize whenever possible: Having fewer box sizes simplifies logistics.

Order samples before bulk purchasing: Test durability and stackability.

Build relationships with reliable suppliers: Consistency in box quality is essential.

Consider environmental sustainability: Choose recyclable or reusable boxes.

Think long-term: Don’t only consider immediate needs; plan for growth and scalability.

Efficient packaging is central to warehouse operations. With the right warehouse packing boxes:

Picking and packing are faster.

Storage capacity increases.

Products arrive intact, reducing returns.

Shipping costs decrease.

Customer satisfaction improves.

Simply put, your choice of packaging is a silent but powerful driver of warehouse success.

Selecting the right warehouse packing boxes requires careful evaluation of materials, sizes, weight capacity, durability, costs, and any special requirements. Whether you operate a small e-commerce business or a large-scale distribution center, the right packaging ensures protection, efficiency, and professionalism.

Remember: your warehouse is only as efficient as the tools you use. Boxes may seem like a small detail, but in reality, they determine how smoothly your operations run. By avoiding common mistakes and considering long-term benefits, you can transform your packing boxes warehouse into a well-organized, cost-effective, and reliable operation.

By continuing to use the site you agree to our privacy policy Terms and Conditions.