©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

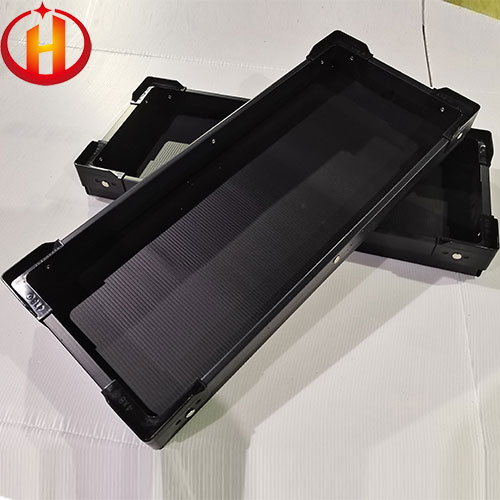

In modern electronics manufacturing, efficient and reliable packaging is essential to ensure that components reach the assembly line or end customer in perfect condition. Among various packaging options, the ESD PP corrugated box has become one of the most trusted solutions for electrostatic-sensitive materials. Designed with electrostatic discharge protection and constructed from polypropylene corrugated sheets, it offers strength, safety, reusability, and cost-effectiveness—making it a preferred choice across electronics, semiconductor, automotive, medical, and precision manufacturing industries.

This blog explores everything you need to know about ESD PP corrugated box for packing: what it is, why it is used, how it is produced, its performance advantages, key applications, customization options, and buying considerations. Whether you are a procurement manager, plant engineer, product designer, or supply-chain decision-maker, this guide will help you select the right packaging solution for your needs.

Electrostatic discharge can damage or destroy sensitive components without any visible sign. Some electronics can fail instantly, while others suffer latent damage that causes breakdown in later stages. Even a small static discharge of:

100V can damage logic ICs

50V can damage memory chips

30V is often below human perception but still harmful

Therefore, preventing ESD is critical during handling, storage, and packaging.

An ESD PP corrugated box prevents static damage through:

Surface conductive or dissipative structure

Charges move safely into the environment.

Anti-static internal environment

The box does not generate static even with friction.

Compatibility with ESD foam trays, dividers, and inserts

Ensures stable protection for multiple components.

For industries with high standards—such as aerospace, cleanroom assembly, or chip handling—ESD-safe packaging is not a luxury but a necessity.

To ensure reliable performance, the production process includes several technical steps:

Polypropylene granules are combined with anti-static masterbatch, conductive carbon powder, or nano additives. Manufacturers choose the formula based on required:

Surface resistance level

Wear resistance

Environmental condition resistance

The mixed raw material is melted and extruded into a lightweight hollow-board sheet (also called flute board or twin-wall structure).

Common sheet thicknesses include:

2mm

3mm

4mm

5mm

6mm

8mm

Thickness is selected depending on load requirements.

Sheets are precision cut into required shapes via:

CNC machining

Die cutting

Laser processing

Boxes are assembled using:

Ultrasonic welding

Rivets

Hot melt bonding

Plastic corner locks

Some products include lids, handles, internal partitions, and printing.

Each batch is tested for:

Surface resistivity

Impact resistance

Weight-bearing performance

Dimensional accuracy

This ensures every ESD PP corrugated box meets industrial usage standards.

PP hollow structure provides high stiffness while keeping weight low. This reduces logistics cost and improves handling efficiency.

Unlike paper cartons that deform after limited usage, ESD PP corrugated boxes can last:

30–50 reuse cycles in rough handling

80–200 cycles in controlled environments

This dramatically lowers long-term packaging expense.

PP material does not absorb water, making it suitable for:

Humid storage

Marine shipping

Outdoor logistics

PP corrugated boxes are unaffected by:

Machine oil

Cleaning solvents

Industrial additives

They are perfect for factories that require clean and chemical-resistant containers.

With surface resistance typically between 10^6–10^9 Ω, the boxes maintain stable electrostatic protection even during:

Friction

Stacking

Vibration

Long-term use

Manufacturers can customize:

Size

Thickness

Color

Surface resistance

Divider structure

Foam or EPE inserts

Printing and barcodes

This ensures perfect compatibility with your production line.

PP is recyclable and generates no pollution during manufacturing or disposal. Many companies use ESD PP corrugated boxes to support sustainable packaging initiatives.

Due to its durability and anti-static performance, the product is used widely across multiple industries.

Ideal for:

PCBs

SMT components

IC chips

Hard drives

Power modules

Sensors

Displays and touch panels

Used in:

Wafer handling

Chip packaging

Cleanroom transportation

IC testing labs

Critical for:

ECU modules

Engine sensors

Vision systems

In-car infotainment electronics

Used in packaging:

Diagnostic modules

Precision components

Micro-mechanical parts

For components requiring high dimensional stability and surface protection.

Whether for production circulation, long-distance export, warehouse storage, or automated logistics, ESD PP corrugated boxes deliver consistent performance.

Different industries have different needs, so customization is a key advantage.

Custom sizes ensure optimal space utilization inside plants and shipping containers.

Common colors include:

Black (most common for ESD applications)

Blue

Gray

Yellow

Custom colors upon request

Users can select:

Anti-static grade: 10^6–10^9 Ω

Conductive grade: 10^3–10^6 Ω

Options include:

Movable dividers

Fixed partitions

ESD foam trays

PP grid trays

PE or EPE lining

These prevent collision and abrasion between multiple components.

Possible additions:

White or yellow screen printing

QR codes

Barcodes

Company logo

Handling instructions

Options include:

Plastic buckles

Velcro straps

Hinged lids

Transparent windows

Label pockets

Hand grips

With the correct configuration, the box becomes more than packaging—it becomes a reliable part of factory automation logistics.

When sourcing, consider the following factors:

Thicker sheets (4–6mm) support higher load and better stacking.

Ensure the supplier can provide:

Surface resistance test reports

Test-by-batch consistency

Long-term stability performance

Look for:

Strong welding or riveting

Smooth cutting

No sharp burrs

Uniform color and surface quality

Select fittings based on your usage cycle:

Heavy industrial logistics → stronger corners and hinges

Cleanroom circulation → lightweight structure with smooth finish

A reliable manufacturer should offer:

Full customization

Technical drawings

Component matching suggestions

Quality tracking system

The right supplier not only delivers products but also helps optimize your production line packaging cost.

The ESD PP corrugated box for packing is a durable, environmentally friendly, and cost-effective solution for protecting sensitive components from electrostatic damage during handling, storage, and transportation. With advantages such as high strength, waterproof performance, chemical resistance, reusability, and complete customization, it has become a standard packaging option in electronics, semiconductor, automotive, and industrial manufacturing industries.

Whether you need standard-size supply or fully customized box production, understanding the material, performance, manufacturing process, and selection criteria will help you choose the most suitable packaging for your business.

If you would like further customization suggestions, design support, or quotations, feel free to ask anytime.

By continuing to use the site you agree to our privacy policy Terms and Conditions.