©Copyright 2019 Suzhou Huiyuan Plastic Products Co., Ltd All rights reserved. Terms and Conditions Designed by iwonder.cnSite Map

Efficient warehouse organization is essential for modern logistics and manufacturing, ensuring smooth operations, accurate inventory management, and reduced costs. A highly effective solution for achieving this is the warehouse storage box with lid. These boxes do more than store items — they protect products, streamline workflows, and maximize storage space.

This article highlights the main benefits of warehouse storage boxes with lids, covering their durability, versatility, reusability, and key role in optimizing warehouse and supply chain efficiency.

The primary purpose of warehouse storage boxes with lids is to protect stored items. Whether you’re dealing with raw materials, semi-finished products, or final goods, dust, moisture, and accidental damage can cause significant losses. The addition of a lid offers a simple yet highly effective layer of protection.

Dust and dirt prevention: In busy warehouse environments, airborne particles and debris can easily contaminate stored goods. Lidded boxes act as a shield, keeping the contents clean and free from dust accumulation.

Moisture resistance: Many lids are designed to fit tightly, preventing humidity or water from seeping in — a major advantage for products sensitive to moisture.

Impact protection: Sturdy plastic storage boxes with lids can withstand impacts, preventing damage during transport or stacking.

This protective capability ensures that the goods remain in excellent condition from storage to shipment, reducing waste and improving overall efficiency.

Warehouse space is always limited — and expensive. To maximize every square meter, businesses need storage solutions that allow efficient vertical stacking. Warehouse storage boxes with lids are engineered for this purpose.

The lids provide a flat, stable surface that enables safe stacking of multiple boxes without risking collapse. Unlike open containers, these boxes distribute the weight evenly, preventing the lower boxes from being crushed.

Benefits include:

Optimized warehouse layout: Vertical stacking makes better use of cubic space rather than just floor area.

Reduced clutter: Organized stacking keeps aisles clear, improving workflow and safety.

Simplified inventory control: Labeled boxes with lids can be stacked neatly, allowing easy identification and access.

In short, these boxes turn chaotic storage areas into efficient, well-structured systems.

High-quality warehouse storage boxes with lids are often made from durable materials like polypropylene (PP) or high-density polyethylene (HDPE). These materials are known for their impact resistance, temperature tolerance, and chemical stability.

Compared to cardboard or wooden alternatives, plastic boxes last significantly longer. They resist cracking, warping, and corrosion — even in demanding environments such as cold storage facilities or outdoor warehouses.

Long service life: Plastic warehouse boxes can be reused thousands of times before showing signs of wear.

Cost-effective investment: While the upfront cost may be slightly higher, their long-term durability results in lower replacement expenses.

Resistant to chemicals and oils: Ideal for manufacturing and automotive industries where contact with lubricants or solvents is common.

In essence, these boxes combine strength with reliability, making them a smart long-term investment.

Organization is key to warehouse efficiency. Warehouse storage boxes with lids play a significant role in systematic inventory management by allowing categorized and labeled storage.

Each box can be designated for specific products, parts, or order batches. Lids ensure that the contents remain undisturbed and identifiable until needed. Many warehouses integrate these boxes into automated inventory systems with barcodes or RFID tags for real-time tracking.

Advantages include:

Quick retrieval: Staff can locate specific items faster, reducing downtime.

Error reduction: Clearly labeled and sealed boxes minimize misplacement and mix-ups.

Better inventory visibility: Helps maintain accurate stock levels and reduces overstocking.

This organization leads to smoother operations, shorter order fulfillment times, and improved customer satisfaction.

Warehouse storage boxes with lids are not limited to one type of warehouse. They are used across a wide range of industries — from manufacturing and automotive to pharmaceuticals, food processing, and e-commerce fulfillment centers.

Some examples include:

Automotive: Storing and transporting spare parts, nuts, bolts, and components.

Pharmaceuticals: Keeping medicines or medical devices clean, dry, and contamination-free.

Food and beverage: Protecting packaged food items or ingredients from moisture and pests.

Retail and e-commerce: Organizing SKUs for quick order picking and packing.

This adaptability makes them a universal solution that supports diverse warehouse environments and operational needs.

With sustainability becoming a top priority for modern businesses, warehouse storage boxes with lids offer an eco-friendly solution. Unlike disposable packaging, these boxes are reusable and recyclable.

Their reusability reduces packaging waste and the need for constant replacement. Many manufacturers now produce boxes from recycled plastic materials, further reducing environmental impact.

Key eco-benefits include:

Reduced single-use packaging: Helps lower waste generated from cardboard or shrink wrap.

Lower carbon footprint: Long-term use means fewer resources consumed over time.

Fully recyclable: At the end of their lifespan, most plastic boxes can be recycled into new products.

By adopting reusable lidded storage boxes, companies can align their logistics operations with environmental goals while maintaining high efficiency.

Transportation is one of the riskiest stages of warehouse operations. Goods often need to be moved between departments, facilities, or shipped to customers. Warehouse storage boxes with lids provide safety and convenience during these movements.

Secure containment: The lids prevent items from falling out during handling or vehicle movement.

Uniform dimensions: Stackable, uniform-sized boxes maximize vehicle space utilization.

Reduced damage risk: The rigid structure minimizes vibration-related damage to goods in transit.

Some models even come with sealable lids or lock mechanisms, providing added security for valuable or sensitive items.

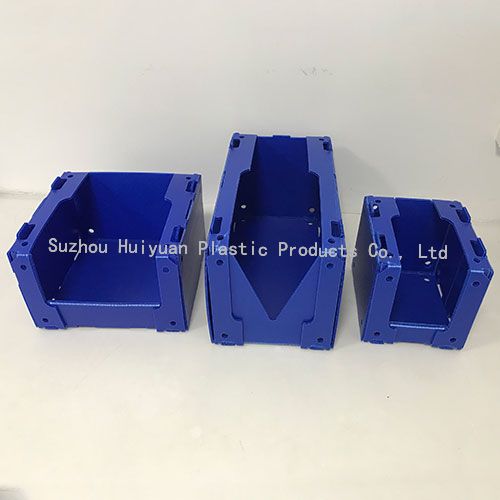

Modern warehouse storage boxes with lids are available in a wide range of designs, colors, and sizes. This flexibility allows warehouses to choose boxes tailored to their specific operational requirements.

Common customization options include:

Color-coding: Helps visually distinguish product categories or departments.

Logo printing: Adds a professional touch and helps identify ownership.

Compartments and dividers: For organizing small components or fragile items.

Wheels or handles: For easier handling of heavier loads.

This customization enhances operational efficiency while reinforcing brand identity in larger logistics operations.

In the modern logistics landscape, efficiency, durability, and organization are vital. Warehouse storage boxes with lids offer all these advantages in one simple yet powerful solution. From protecting goods and saving space to improving sustainability and safety, their benefits are undeniable.

For warehouses looking to upgrade their storage systems, investing in high-quality, reusable lidded storage boxes from Suzhou Huiyuan is not just a practical choice — it’s a strategic move toward long-term success. These boxes embody the principles of modern warehousing: organized, efficient, and environmentally responsible.

By continuing to use the site you agree to our privacy policy Terms and Conditions.